Water-borne vessels such as ships, yachts, boats, and jet skis require durable and long-lasting paint jobs to withstand the elements. In addition to sun and air, marine coatings are exposed to and submerged in water. Protecting a substrate from submersion in water and particularly saltwater can be a difficult task because you have to deal with the possibility of organic growth on the surface in addition to deterioration from exposure. The coatings required for this type of environment often require a correct and consistent climate for application. Accudraft designs marine paint and refinishing booths to create the ideal environment for applying specialty marine paints and anti-foul coatings. Temperature, humitity, air flow, and exposure to compounds are tightly controlled to provide the correct environment for application and curing of marine coatings as well as to meet code for safe and efficient operating conditions.

Because efficiency and repeatability are important in almost every process, Accudraft works with our customers to make sure they are getting enough paint booth to meet their needs without having excessive unused space in the booth. In the case of an operation that paints one type of vessel over and over, it may be smart to conform the shape of the booth to the vessel so save on required air volume through the cabin. If the operation allows for painting of parts off of the vessel, it may be wise to explore smaller parts booths so that the large components and small component painting spaces are each optimized for their role in the overall process. By working with the end user to understand their particular needs and areas where they can gain efficiency, our team can make recommendations that allow them to operate effectively and efficiently over the longer term.

In larger marine paint booths where a conformed design is applicable, items like hoses, reels, electrical drops, air, and water can be installed closer to where they will be needed. Curtains can also be integrated into the paint booth design. They can be drawn down to isolate the painting spray area or make several areas for prepping parts, substrates, or spraying marine paint coatings. If radiant heat technology is used to heat the substrate, the sections are closer to the watercraft body being painted. This offers better heat distribution across the parts which in turn aids in more even flashing of the products being applied.

It can be a challenge to move marine vessels on dry land. Special rails or other means may be required to load and unload the booth. Additionally, raised platforms or man lifts may be required to safely and effectively reach the full height of vessels.

When spraying specialty marine paint or anti-foul coatings on large boats inside a paint booth, the size becomes a significant analysis point by engineers. When conditioning air, it is crucial to understand precisely how much energy is used to achieve near-perfect air conditions. Marine coating manufacturers typically disclose the exact standards for air temperature and humidity levels to ensure proper performance. Marine-specific paint booths can require heating and cooling, as well as humidification and dehumidification, to achieve those perfect air conditions.

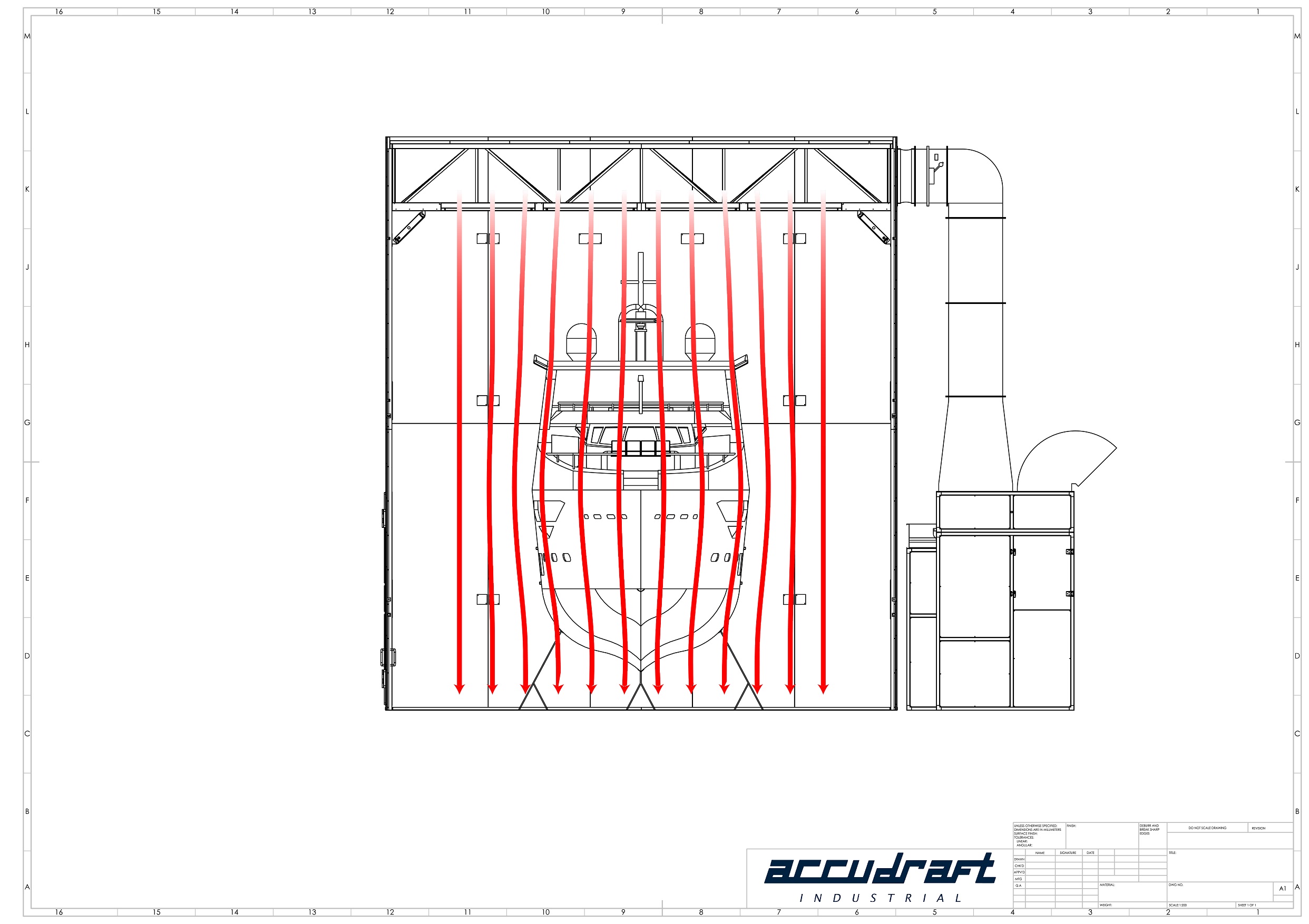

Moving the air through a marine paint or refinishing booth can be challenging due to the watercraft’s shape. Oddly shaped vessels can affect the air flow pattern and, if not addressed, can result in unfavorable spraying conditions. By keeping the air flow moving freely,lingering overspray is minimized, and operations run more efficiently. Application methods are also important to consider. Will the majority of the paint jobs on a boat be new gel coatings and be applied with an HVLP spray gun? Or will the majority of the boat refinishing work consist of roll-on anti-foul hull coatings?

Getting air to flow freely is imperative, but so is Air volume to achieve the correct air velocity. Airflow and air speed LFM specifications for paint booths are required by OSHA, NFPA, and the department of environmental protection. Using recirculation can help to achieve the required air velocity through tha cabin and around the vessel or component using much less energy than trying to treat 100% of the air to provide the required volumes and velocities. The other area of operation that can benefit greatly from recirculation is curing. In applications where elevated curing temperatures are required, recirculating used air back across the burner or heating coils can allow higher temperatures to be achieved while still maintaining air speeds through the cabin and using far less energy than required to achieve the same temperatures in a single pass of the air across the heater. Our engineers can help develop a recirculating system that fits your application while still adhering to all required safety codes.

Heat reclaim is another valuable tool. On a large watercraft paint booth, reclaiming heated air can save thousands of dollars per month. There is no need to Lose all of the energy from heated air during booth operations. Where reclaim differs from recirculation is that the air being exhausted from the booth is passed in such a way that it tempers the air going into the air makeup. This allows the heating and cooling operations in the AMU to be a lot more efficient keeping heating/cooling costs down. A reclaim system can temper the incoming air regardless of which mode the booth is operating in. The bigger the marine painting application, the more the user will save with heat reclaim.

A major part of boat refinishing services is preparing the surface of the boat to receive a new gel coat or hull anti-foul coating. When applying new gel coatings to boats and marine vessels, the old surface must be prepared prior to spraying a new gel coating. Typically, the old gel coating is dull or chalky. This old coating or the fiberglass substrate of the boat body or hull must be sanded and scuffed prior to spraying new gel coatings. This creates a considerable amount of dust and debris inside the boat re-painting shop. Dust can be flammable and dangerous to breathe since it may contain carcinogens and fiberglass particles. Containment of marine gel coat sanding is essential to a properly outfitted boat re-painting facility because it reduces the amount of extra cleanup time between jobs. Minimizing airborne dust particles (particularly fiberglass particles) is also a huge step forward for the safety of your employees. OSHA is very specific about separation of airborne particulate from employees and minimizing at the source is a great way to start eliminating exposure. In situations where aluminum hulls or parts are being sanded, the containment of the released aluminum particles are even more important for health and safety reasons. Prep stations with curtains and exhaust filtration walls are available to help keep the worker healthy and also keep the facility clean.

Anti-foul coatings that will be applied to the underside of the boat also need a lot of surface prep. First, the existing fouling elements such as algae, barnacles, and other mollusks must be removed. Then the original anti-foul coating must be removed or at least sanded in order for the boat hull to receive a new anti-foul coating, which will last years. Proper adhesion of the anti-foul coating is extremely important for the coating to perform as described by the manufacturer. Anti-foul hull coatings have a very specific chemistry that is designed to perform considering the friction of water. As a boat travels across the water, anti-foul coatings are designed to self-clean or self-polish. This keeps the anti-foul coating slick and prevents it from releasing the integrated biocide that is in the coating itself. A proper anti-foul coated hull can save thousands of dollars in fuel by reducing the boats drag over the water. This coating is very particular and must be applied in the proper conditions. Anti-foul coatings also contain harmful compounds such as biocides that are designed to kill life and stop it from growing on the hull. This is in addition to the normal VOC’s that are present in most paints. Anti-foul should be removed and applied in a properly ventilated environment to ensure the employee safety and environmental safety of the neighborhood around the shop.

The control system for a paint booth that utilizes advanced safeties, advanced filtration and precise control of the spray area has to be robust enough to withstand life in a paint shop and advanced enough to deliver repeatability in the conditions and performance of the booth. Generally the control system is designed for a particular booth to achieve the required specifications. Some specifications deal with the safeties, air flow, climate and other items that are characteristics of the booth but there are some other features that may be required of the controls such as data logging/reporting, BMS integration and interaction with the building fire alarms or other building safeties. The control systems used for these advanced booths are wide ranging in their particular configurations but they all have some common features.

The HMI (Human Machine Interface) is the point of interaction for the operator to “tell” the control system what it should do and also the place where the paint booth displays data about conditions, alarm status and other information that the operator needs. While smaller booths generally have one HMI, it is not uncommon for larger booths to have multiple HMIs spread along the outside for convenience and even HMIs at the air makeup units for maintenance technicians to use when diagnosing problems.

PLCs (Programmable Logic Controllers) are essentially computers that can be custom configured to allow the paint booth to operate as required. A PLC control setup allows the manufacturer to control what features the operator has access to, what information they can see at the HMI, alarm thresholds and all of the logic that keeps the booth operating at the correct conditions. The logic programmed into the PLC ultimately controls air volume (possibly varying air volume in different modes), percentage of recirculation, temperature, humidity, operational sequencing for alarm conditions.

Variable Frequency Drives (VFDs) allow the motors to be run at different speeds to maintain correct air flow in varying modes, overcome filter degradation, maintain the correct percentage of recirculated air versus fresh air and exhaust air as well as allowing for a much more energy efficient stopping and starting of motors/fans. The VFD or VFDs receive a signal from the PLC that dictates the time to start as well as what speed they should be operating at. Once the VFD has the signal it varies the voltage and frequency sent to the motor to achieve the correct result.

Placed all over the booth are sensors and safeties that monitor the actual conditions of the space and process. These items are constantly sending information to the PLC where it is processed and analyzed so the correct adjustments can be made to keep the system operating within specifications. The exact type and number of sensors or safeties will vary by application but the following is a list of the most common: cabin temperature, cabin humidity, high temperature limit safety, LEL monitor, VOC monitor, door switches, pressure sensors/switches, intake air temperature at amu and amu discharge air temperature.

On large and small paint booth applications, the controls of the paint booth are occasionally tied into the Building Management System (BMS). The BMS as a whole can control/monitor all aspects of a buildings operating conditions: lighting, pumps, hvac, security, fire alarms hot water plants, and cold water plants. Depending on the level of dependency required by the facility, the BMS connection for the paint booth can simply monitor the conditions at the booth but the most advanced systems can record data from the booth during processes and even control the operation of the paint booths or individual motors. Tying the paint booth control into a BMS system can be done for a number of reasons including safety, energy usage tracking, security and quality control but no matter the reason why, the integration of the paint booth controls to the BMS requires close coordination between the customer’s facilities team and our engineering group to make sure the appropriate provisions are made to accomplish the mission.