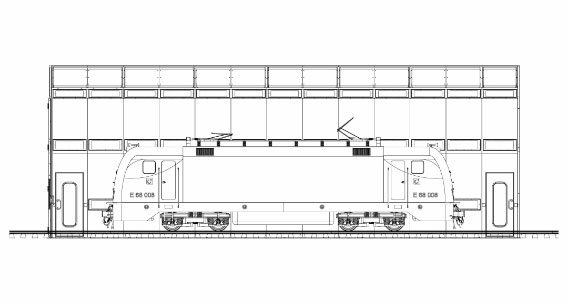

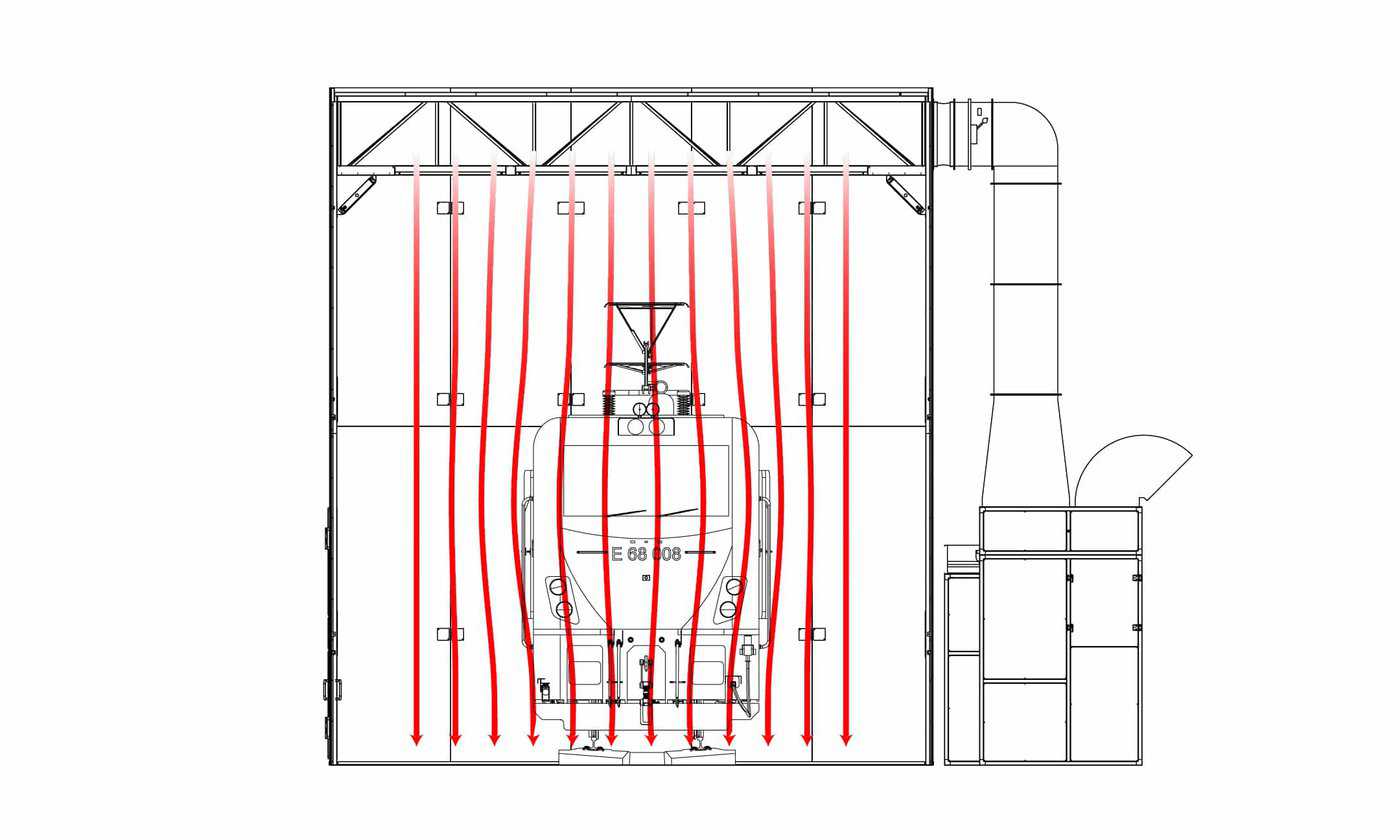

The height, width, and especially length of train cars plays a part in the train paint booth’s overall shape and layout. Depending on the work being performed on the train, Booths can be designed to reduce the overall volume of the paint booth’s interior. By making a design that accommodates the train car’s body, but also takes into account the work being done, the overall airflow needed can be optimized. This will minimize the overall airflow, heat, and contamination control. A custom design will significantly reduce the size of the air handlers needed and the overall energy required to condition the paint booth. The rail paint or refinish booth will save energy every day for the life of the installation. If a rail refinishing facility is primarily focused on refinish of parts on the car, a paint booth system may be engineered completely differently compared to a facility that is built for manufacturing of train cars where most parts are painted off of the railcar and are later installed. For refinishing or refurbishment of railcars, there may be a happy middle ground where a very large 150-foot-long paint booth can be divided into several smaller paint booths with divider doors. This is just one example of custom solutions that Accudraft engineers every day. This would allow the facility to use the entire paint booth as one long paint booth when painting entire rail cars or locomotives or use a much smaller space or combination of sections of the booth for parts painting. This way the facility is only using up the energy they need to paint and heat the rail car or parts. No need to fire up the entire paint booth system every time in you only need a small area.

Curtains can also be integrated into the paint booth design. They can be drawn down to isolate the train painting spray area or make several areas for prepping parts, substrates, or spraying paint coatings. If radiant heat technology is used to heat the paint booth, the sections are closer to the body of the train car or locomotive being painted. This offers better heat distribution as well as the painters or workers working in the booth. Trains can be challenging to move when not on rails because of that special rails or other means may be required to load and unload the booth. Additionally raised platforms or manlifts may be required to safely and effectively reach the full height of larger locomotives, trains and rail cars.