PAINT BOOTHMAINTENANCE PLANS

PAINT BOOTH MAINTENANCE PLANS

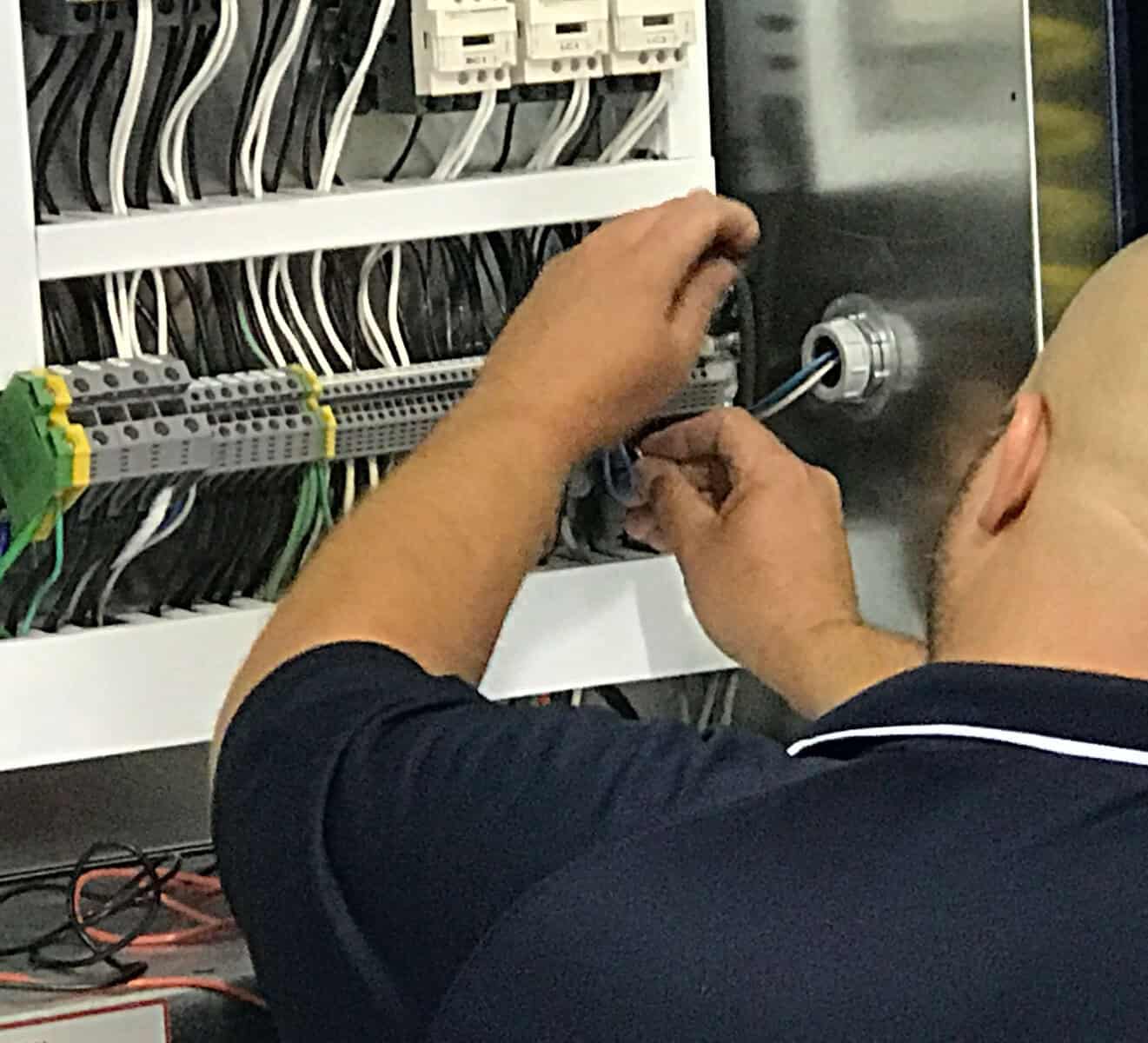

Proper and regular maintenance for all finishing systems is necessary to preserve the equipment’s consistency and longevity. With so many intricate working parts, air handling components, and unique filtration systems, many facilities choose to subcontract preventative maintenance to Accudraft. Our paint booth maintenance plans include mechanical component examination and servicing, filter replacement, light fixture inspection, bulb and ballast replacement, and booth cabin cleaning.

WHY IS PAINT BOOTH MAINTENANCE IMPORTANT?

The focus of paint booth maintenance is to maintain the equipment in its most efficient state. It is critical to have proper and regular maintenance completed by experienced technicians who can ensure key components are working optimally to prevent costly repairs and production backlog. Too often, shops suffer from expensive and extensive repairs, leading to lengthy shutdowns that could have been avoided with routine maintenance. Remember, maintenance plans are to prevent repair—they’re not a service call.

WHAT IS INCLUDED IN A MAINTENANCE PLAN?

Whether you have Accudraft equipment or another manufacturer, we offer custom maintenance plans that are specifically tailored for your facility. Your personalized plan will provide a detailed schedule of specific manufacturer guidelines that emphasize how often key components should be inspected, cleaned, or replaced. For example, high-performance shops may require monthly maintenance, whereas a shop that paints infrequently may be able to do bi-annual maintenance. Accudraft understands that the equipment you elect for your shop is a big investment, and we want to support your business and future.

HOW TO SCHEDULE A PAINT BOOTH MAINTENANCE

If you are interested in exploring how Accudraft’s custom maintenance plans can keep you worry-free and bottleneck-free, call us at 1-800-524-0340 or contact us online.

Quote