As a start-up shop, sometimes choosing the right paint booth can be a bit tricky.

The term “paint booth” is very broad and can mean anything from a basic enclosure with a fan to a high production paint booth that includes many other features and systems incorporated.

Sometimes a shop owner may be looking for a fully heated, high production type of paint booth off the bat where a start-up shop may want to start with a basic non-heated booth and have their paint booth grow with them as their rate of production increases. Depending on the shop owners plans, one type of booth may be a better choice than another.

In this blog post, we will be breaking down the basic types of paint booths and their advantages and disadvantages in terms of performance, cost, and most importantly, their flexibility in the future.

Any start up shop that is looking to install a basic non-heated paint booth should carefully consider what is right for them now and what will be right for the future. First we will define the four main types of booths we see in the automotive market and their relative pros and cons in terms of airflow and performance. Afterwards we will look at adding heat (air makeup units) to each and see how that may affect the buyer’s choice.

Definitions of Each Type of Paint Booth, Advantages, and Disadvantages

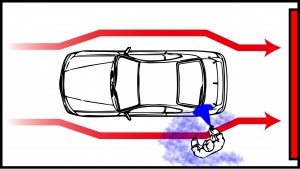

Crossdraft Paint Booth Airflow Concept

Crossdraft Paint Booths

A crossdraft paint booth flows air directly across the vehicle or the object being painted. Crossdrafts are the most popular paint booth found in the automotive and truck industry since they are the most economic answer to meeting codes for anyone painting in their facility. The incoming air is drawn directly through the main doors or through filtered columns in the front corners of the paint booth workspace. The exhaust is achieved through the back wall or another set of columns in the rear.

Advantages of Cross Draft

Crossdrafts are very economic for two specific reasons:

- First, the paint booth is breathing from the front and not through the ceiling so the paint booth cabin is constructed without the upper plenum that would be necessary in other types of paint booths. This means that out of all the types of paint booths out there, a crossdraft is manufactured with the least amount of material possible. The cost from the paint booth manufacturer should be the least out of all the different types they offer.

- The second and biggest reason for low cost is that a crossdraft does not need any concrete work (such as downdraft pits) to function. Crossdraft paint booths can be installed right on an existing floor. Concrete work can be very expensive and a crossdraft paint booth keeps that out of the equation for the buyer.

Disadvantages of Cross Draft

- The shape of the air draft through a crossdraft is not ideal due to the fact that it is a linear path across the entire painted object. If for instance, a piece of dust or dirt is present anywhere in the airstream, it has a lot more ground to cover before it makes its way safely out of the paint booth.

- Contaminants stand a much greater chance of landing somewhere in the new finish since the draft is dragging everything across the entire vehicle or object. Other types of drafts draw the overspray and airflow AWAY from the object quickly.

- Also the painter is usually in the way of the airflow. For example, when the painter is applying the coating, the overspray must exit the REAR of the booth and if the painter is standing anywhere in the paint booth except the very front (near the main drive-in doors), the paint overspray may have to travel over or around the painter to get out. This can cause additional dust/dirt pickup and contamination of the finish and will also expose the painter to unhealthy substances.

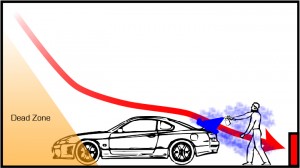

Semi Downdraft Paint Booths

Semi-downdraft paint booths operate much like a crossdraft since the exhaust is still achieved via the rear of the paint booth workspace, however the incoming air is now introduced to the workspace through small section in the ceiling located at the front of the paint booth.

This creates a draft pattern that is directed at a diagonal from the filtered area of the ceiling to the exhaust point at the rear of the paint booth.

Advantages of Semi Downdraft

- The airflow pattern gives a slight advantage over crossdraft paint booths since the incoming air is not going across the painted object but rather on a diagonal heading somewhat downward.

- A semi downdraft paint booth is also a very economic choice since concrete is not necessary and the cost of the unit is generally a mid-range price from most paint booth manufacturers.

Disadvantages of Semi Downdraft

- A semi downdraft paint booth still suffers from the fact that the painter is most likely going to be in the way of the draft and will be exposed to more overspray than need be.

- Additionally, the downward or diagonal shape of the draft, can create a dead zone at the front of the paint booth that gets little or no airflow.

- The painter must think ahead and position the area to be sprayed toward the back to get the best air flow. If a part or area of an object must be painted at the front of the paint booth, the area may not exhaust properly or even worse, the overspray may begin to swirl in the dead zone, picking up dust or dirt from the floor and laying it into the finish.

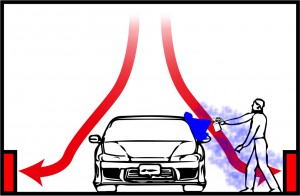

Side Draft Paint Booth Air Flow Concept

Side Draft Paint Booths

Side-draft or side-downdraft paint booths operate by introducing air through the ceiling and exhausting the air through the side-walls. The entire ceiling is filtered and the entire or vast majority of the length of the paint booth’s walls are filtered for exhaust.

Advantages of Side Draft

- A side-draft paint booth creates a more even pattern of airflow around the painted object and draws paint overspray and contaminants DOWN & AWAY from the finish.

- Side draft paint booths also do not need concrete pits to function so the added cost of concrete work is eliminated for the buyer.

Disadvantages of Side Draft

- A side downdraft paint booth is usually the most expensive model from any paint booth manufacturer since there is a full upper plenum constructed above the workspace and the side walls must include ductwork and exhaust fans to achieve the exhaust. In terms of material, it is the most expensive type of booth to manufacture.

- When comparing the saved concrete cost however, this could possibly be justified since it is giving the user a very good draft pattern far superior to a crossdraft or semi-downdraft paint booth and still does not need concrete work. The problem with the paint heading toward the painter still exists in a side-draft and cannot be avoided.

- In a side draft paint booth, the coating must be sprayed by the painter and the overspray must exit directly behind him.

- The problem with contaminants or picking up extra dust is reduced since the air is being pulled away from the vehicle, but the possible exposure to paint overspray is still present if the painter isn’t wearing the appropriate breathing apparatus.

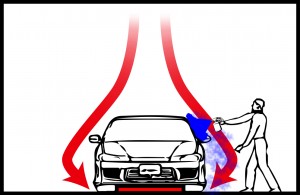

Downdraft Paint Booth Air Flow Concept

Downdraft Paint Booths

A downdraft paint booth produces a draft pattern that is straight down from ceiling to floor. Downdrafts may need concrete pits or may be raised on steel basements with drive-up ramps.

Advantages of Downdraft

- The biggest advantage to a downdraft paint booth is cleanliness. Air is drawn around the vehicle or painted object and exhausted from underneath the object.

- Downdraft paint booths pull paint overspray and contaminants downward and away from the painted object no matter where the painter is spraying.

- The risk of dust and overspray contamination is greatly reduced and the painter is also in a much safer environment since the overspray is pulled immediately downward and away from the painter no matter where he is standing.

- Finishes are generally cleaner and can translate to money saved by reducing buffing and corrections after the finish is dry.

Disadvantages of Downdraft

- A downdraft paint booth needs concrete pits and tunnels to function. The paint booth manufacturer may offer a pitless design where the entire paint booth and mechanicals are installed on a raised steel basement with drive-up ramps.

Either option represents a significant cost that must be weighed by the buyer.

Adding Heat & Bake Capabilities to Each Type

A major consideration when buying a basic non-heated paint booth is the addition of a heated air makeup unit later on.

A custom shop may never need heat and production upgrades but if volume ever becomes part of a shop’s business model, it is imperative that they add heat to their paint booth in order to stretch the overall capability of their existing facility.

If a start-up shop purchased a basic non-heated paint booth and has done a good job at marketing themselves and developing repeat business, they could find themselves in this position pretty quickly. Costs and challenges in heating the four different types of paint booths can vary.

Here is a quick breakdown on the addition of heat as it relates to the four types of paint booth covered above.

Heat recycling is also very important when adding heat to a paint booth since it can save thousands per year. The ability of including heat recycle is also noted on each type.

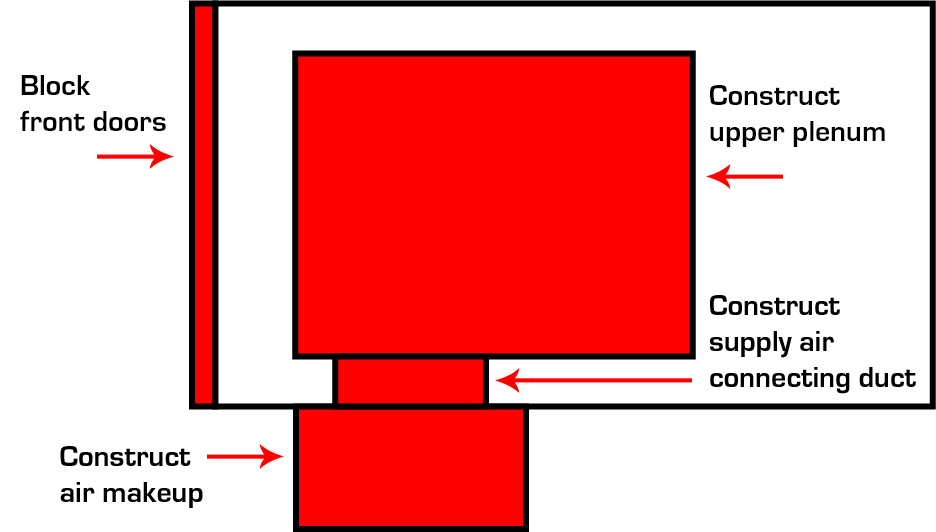

Adding Heat to Crossdraft Paint Booths

The most economic paint booth available is typically the most expensive to retrofit with heat in the future. The buyer must keep that in mind when the original purchase is made.

If production is the goal for the buyer, heat is definitely in the picture either now or in the future. A crossdraft paint booth delivers air through the doors or through columns in the front of the booth. Heat would have to be supplied through either of these places in order to work.

Adding heat to columns can take some extra ducting and creative customization by the installer which adds to labor and material costs above and beyond the cost of the air makeup unit and controls that may already cost $10,000 or more. If the crossdraft paint booth breathes through filtered main doors, there is no way to add heat to the doors without blocking the way into the booth so the doors must be sealed and an upper plenum must be constructed on site by the installer.

The interior ceiling must be cut open and framed for filters thus converting the crossdraft into a semi downdraft. This becomes extremely expensive and may even throw the idea out the window until the owner can afford a new heated paint booth.

Heat Recycle

Possible in certain configurations of crossdraft but achieving it will not be cheap or easy. Most installations would not be in a position to retrofit a heat recycling air makeup unit in a cost effective manner.

Adding Heat & Air Makeup to A Crossdraft Paint Booth

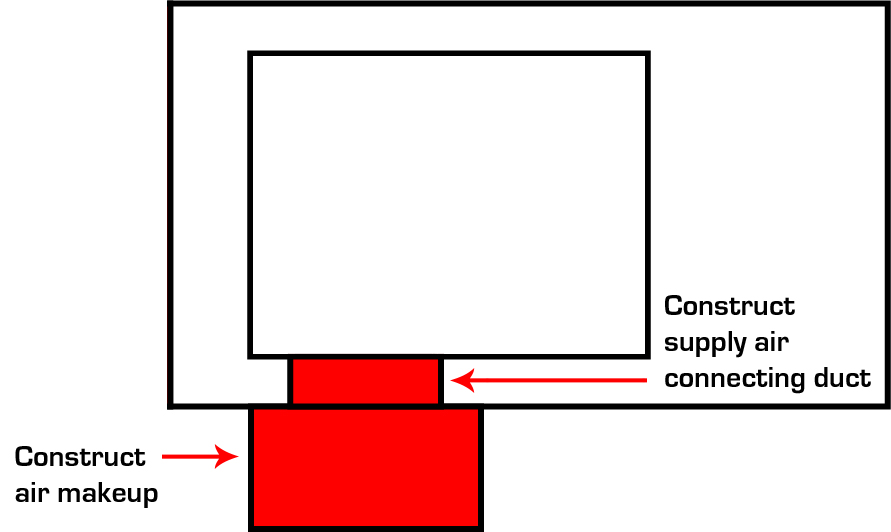

Adding Heat to Semi Downdraft Paint Booths

Relatively easy to retrofit with heat. The upper plenum that is supplied with a semi downdraft paint booth makes heat an easy retrofit.

The paint booth air makeup unit can be stood right next to the paint booth and fed right into the top plenum. Very little on-site work or metal customization is necessary since the cabin has the plenum. Labor costs should be reasonable and the installation should be straight forward for the installer.

Heat Recycle: Most likely difficult and/or expensive since the exhaust is still at the back of the paint booth and the heater is at the front. Connecting the two would be expensive and need a lot of ductwork.

Some installers may cut a small opening into the booth wall where the heater is standing and feed some of the booth air back into the air makeup unit when the paint booth is in the bake cycle but a true 80%+ heat recycling system is generally not seen.

One easy possibility exists if the heater can be hung above the paint booth or can be put on the roof of the building, then a true heat recycling system can be retrofitted by connecting the exhaust duct at the rear of the paint booth to the air makeup unit and have the air makeup unit feed the upper plenum.

Adding Heat & Air Makeup to A Semi Down or Modified Downdraft Paint Booth

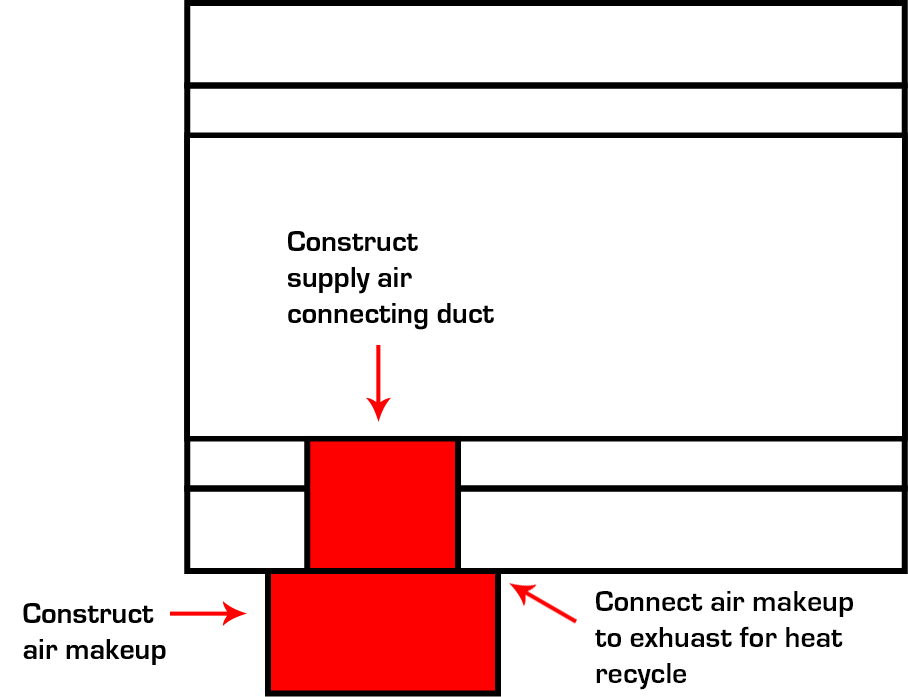

Adding Heat to Side Downdraft Paint Booths

Easy retrofit of heat and heat recycle. A side downdraft paint booth has ducts that run along the side walls and has a full upper plenum.

This not only makes adding heat easy since the heater can be fed into the upper plenum anywhere along the length of the paint booth but it also makes heat recycling possible since the heater can be connected to the exhaust duct anywhere along the length of the paint booth.

Heat Recycle: Most likely easy and cost effective.

Adding Heat & Air Makeup to A Side Down or Side Draft Paint Booth

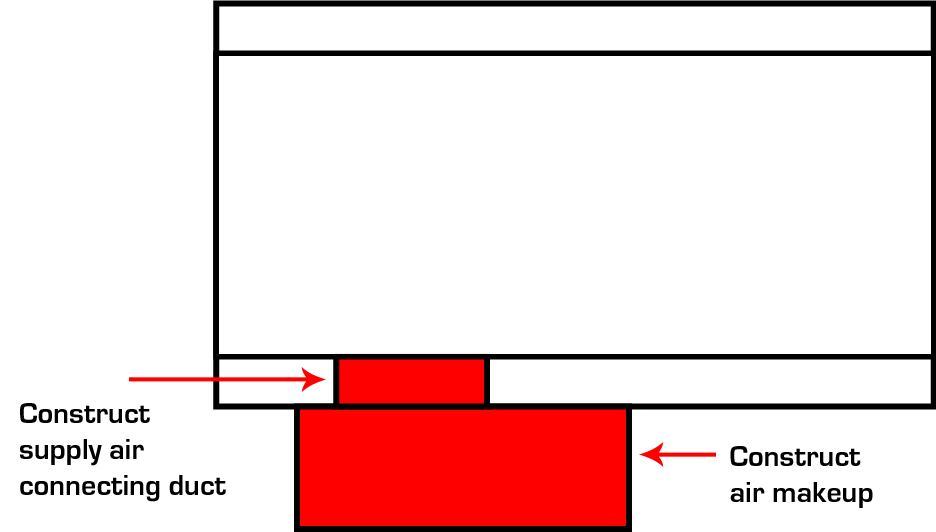

Adding Heat to Downdraft Paint Booths

Heat is also easily added and heat recycle can be possible.

Different layouts of the existing paint booth may make the addition of heat easier or more difficult but little or no modification to the existing cabin is necessary thus keeping some of the installation labor costs down.

The components that are necessary (The heater, controls, and safeties) represent the major cost of the upgrade.

Heat Recycle: Most likely easy and cost effective.

Adding Heat & Air Makeup to A Downdraft Paint Booth

Recommendations Before Choosing the Right Paint Booth

- Leave enough room around the booth itself to add heat in the future and make sure you go over the intended plan with your paint booth salesman or distributor. Use their knowledge to your benefit and ask them their opinion on what you may want to do in the future.

- Make sure the electric load needed for an air makeup unit is available in your building. Make sure you know WHERE the power will need to be run from and the associative cost from an electrician.

- Make sure the fuel (natural gas, propane, or oil) is available and can be brought to the heater and make sure you are aware of the associated costs.

- Check with town authorities ahead of time and make sure that the addition and position of a heater is allowed even if you are not purchasing it with the paint booth today.

Consider the challenges shown per model above and choose wisely! Always think ahead when purchasing a paint booth. Think about where you are now and more importantly WHERE YOU WANT TO BE “x” number of years from now.

It may seem like a lot to consider, but try to ignore the “lets just get going and figure it out later” feeling. Selecting the right type of paint booth and developing a well laid out floor plan will save you thousands in the future.

It’s definitely worth a day or two of creative thinking and planning ahead. Good luck out there!