Originally published on 8/1/2022 in Products Finishing magazine.

Automation, digitization, connectivity, remote process management tools help automakers, suppliers paint parts, vehicles at lower cost, reduced carbon footprint.

Industry 4.0 tools of automation, digitization, connectivity, traceability/transparency, and remote process monitoring and troubleshooting — incorporating machine learning — are having powerful impacts on many aspects of the manufacturing environment, and the automotive painting segment is no exception. Benefits achievable when the physical world of manufacturing is connected to the digital world of big data, predictive algorithms, and decentralized data processing and decision making include significantly higher overall equipment effectiveness (OEE), less downtime, fewer errors plus the ability to predict (and fix) issues before they occur, lower energy usage, reduced paint/solvent/water usage, higher productivity and profitability, and concurrent reductions in costs, waste, and lead times. During a period when manufacturers in many regions are struggling to meet staffing requirements, and to manage supply shortages and energy and raw material price volatility, the enhanced collaboration that smart technology makes possible not only within a company but also between a company and its suppliers and customers can make a good company great and a great company a global competitor. What follows are four suppliers making important contributions to this segment.

Founded in 1981, Randolph, N.J.,-based Accudraft (SAIMA of North America Inc.) is a leading manufacturer and systems integrator for the spray-finishing industry. The company engineers, builds, and installs spray-finishing systems and enclosures throughout the Americas for customers ranging in size from individual collision shops to management services organizations (MSOs) operating numerous facilities. Customers hail from the automotive, commercial truck, aerospace, marine, and rail markets. Additionally, the company maintains and services and conducts onsite emergency repairs for its own equipment and that from other companies. To support its line of paint booth enclosures, Accudraft developed two products that address Industry 4.0 needs for increased connectivity, automation, and real-time data access.

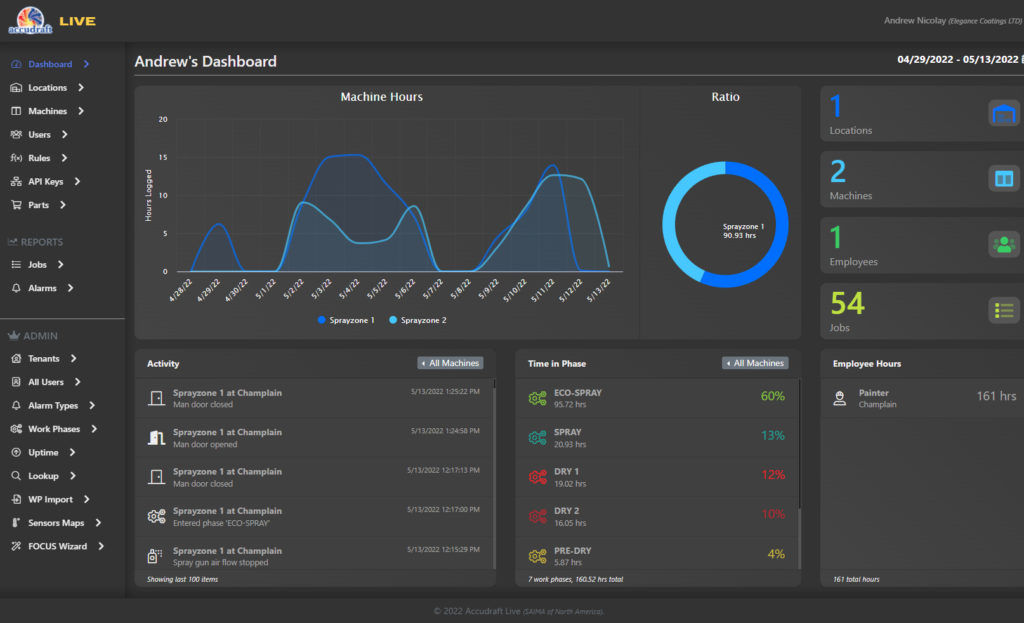

Accudraft LIVE is described as a mobile-friendly, cloud-based solution for monitoring the performance, costs, and technical metrics of a single paint booth or multiple factories’ worth of paint booths. Among the real-time data accessible via the program to streamline the painting process and schedule maintenance are total hours run by any booth, making it easy to track OEE; hours logged by phase, which helps identify system bottlenecks; hours logged by employee; total costs per day to operate a single booth or to compare multiple booths with each other; number of items painted per day, and length of each job. The system also logs uptime and schedules maintenance, then sends reminders when services are due. Replacement parts and filters can be ordered with the touch of a few buttons, helping maximize uptime. As a first-party app, only the end-user/owner can view data and grant access to other users (be it the shop manager, painter, or even an outside supplier).

Accudraft FOCUS is a 15-inch/38-centimeter touchscreen control panel that provides access to online Accudraft LIVE services, including technical support. Users can configure and store up to five separate paint programs and up to 99 different environmental spray settings — including airflow, bake temperatures, multiple flash settings and curing cycles, and cool down — using the FOCUS panel.

“Instead of constantly adjusting for different materials, with our FOCUS panel, the end-user can have multiple preprogrammed settings for different coatings and environmental settings all customizable so products can be finished faster and more efficiently than before,” adds Jeremy Winters, Accudraft content creator.