When considering to buy either a new or used paint booth, analyzing energy efficiency is key. Many old or used paint booths may not have all the features available today and can cost the shop over 50% more to run day in and day out.When analyzing either a new or used paint booth for energy efficiency, make sure to address the three main features listed below.

Direct Fire – Probably the biggest leap in paint booth technology in the last 30 years.

Originally paint booths were made with INDIRECT fire heaters since flammable substances were being introduced into the atmosphere but around 25-30 years ago, a few manufacturers found a way to engineer paint booths that could use direct open flames as their heat source. This revolutionized the industry and quickly became the standard that we still see today. Direct fire is 30% more fuel efficient off the bat and should be the only consideration regardless if someone is looking at a new or used paint booth. What a buyer needs to look out for are old paint booths or even newer paint booths that still carry indirect fire heating systems as their standard. Many foreign made paint booths still arrive in the US with indirect fire systems simply because they have no other option to offer the buyer. Including direct fire in a paint booth system requires a lot of investments by a manufacturer including design/engineering, certification, and stamps of approval. Many foreign manufacturers and some importers cannot make those investments and still sell indirect fire units today. The buyer CAN convert indirect fire systems to direct fire but it will require new heating elements, modifications in the field, and new controls. This is something that the buyer will have to add to the price of the used paint booth and make a decision whether the price tag makes sense at that point.

Heat Recycle – Another technological advancement that changed the industry standard.

Recycling of heat is another feature that needs to be analyzed. If the system is not made to recirculate, the paint booth can burn even more fuel than is necessary. Many paint booth manufacturers to this day offer paint booths that do not recirculate. Some may say “fresh air” recycle, this is not a true recycle of heat. This just means that a portion of the incoming air is run past the burner twice in order to heat the air faster. After the air has passed through the workspace, it is still expelled out the exhaust stack. What the buyer should look for is a true heat recycle system that has return air from the workspace. This is either accomplished via a downdraft pit tunnel or connecting duct that leads back to the intake unit. Make sure any used booth being considered has heat recycle of at least 80-90% and if you are looking at a used booth, make sure all the connections and dampers are working properly. Making a used booth recycle heat when it wasn’t designed to may be possible but can be expensive and may also void any certifications or manufacturer support on the product.

Variable Frequency Drives – VFD’s can provide 3 major energy saving features to a paint booth.

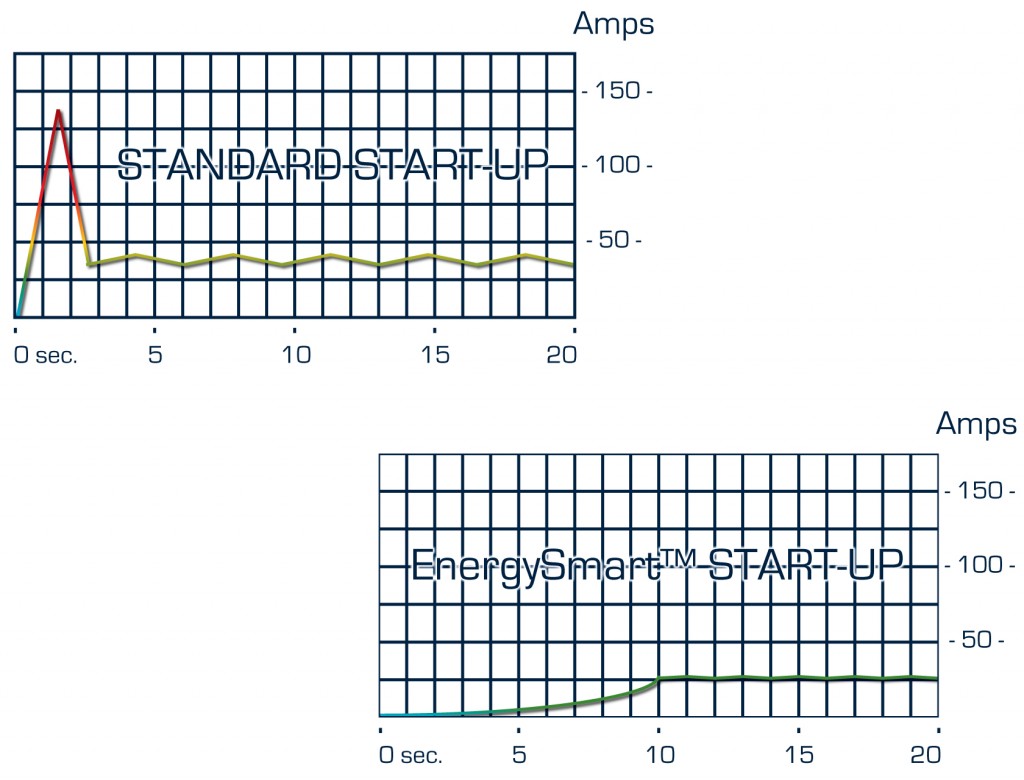

1. Motor Soft Start – Traditional motor start-up on your paint booth or prep station mechanicals causes a spike in power draw. Most utility companies charge a service factor and rate the body shop according to the highest possible power draw in order to protect the overall electrical grid for the area. For example: If a motor on your paint booth is rated for 25-30 Amps of running power, the motor draw may spike to over 100 Amps momentarily as the turbines wind up from a standstill. After a few seconds, the power draw levels out, but the damage has been done. The body shop will now be charged according to the “spike” rate, not the lower running rate.

With the use of VFD’s (Variable Frequency Drives) on your paint booth, motors are gradually started in order to get the exhaust and air makeup turbines spinning. Each VFD drive continues to increase each motor’s speed until the proper amperage is reached. This eliminates the spike in power and can save 30% or more on electrical usage.

2. Auto Pressure – The use of VFD’s also gives the user the ability to speed-up or slow down the fan RPM which gives them great control of the cabin pressure. Maintaining proper pressure when painting in the workspace is key to not only providing the proper airflow and evacuation of overspray, but also to producing a clean paint job. Fast evacuation of overspray and fast airflow aid in flash speeds and better application while keeping pressure slightly positive will keep the work environment clean. A newer smart control panel or PLC should allow for the VFD drives to automatically maintain pressure inside the spray area by adjusting turbine speeds accordingly. This eliminates wasting electricity and fuel by running the paint booth just as much as needed to equalize pressure. It also takes the back and forth out of the painter’s work day when trying to set good pressure in the paint booth. The system will automatically realize when filters are getting clogged and add power to the fans in order to compensate.

3. Economy or Standby Mode – There are also new smart control panels on the paint booth market today that can give you“standby” or “economy mode” where the VFD drives will drop all processes to idle when the spray gun is not in use. This ensures that the system runs at full power only when the painter is spraying and that it idles whenever the painter is away. Countless electrical and fuel dollars are wasted in any facility when the painter is either in the mix room or is pulled away for another task while the booth is running at full power. A paint booth with economy mode can save thousands in both electrical and fuel energy usage over the course of a year.

With the combined power of VFD’s and a smart control panel, systems can save anywhere from 30-50% in electrical and fuel costs.

VFD’s can be added to any booth to reap the soft-start benefits for the fan motors however, the biggest energy saving technologies that VFD’s can offer are the built-in features like automatic pressure control and paint booth “economy Mode”. If the paint booth being researched is new, these features should be included. If it is a used paint booth that is relatively young (say 10 years old or less) these features may already be part of the control programming (if you get your make, model, and year you could check with the paint booth manufacturer as well). Ask the seller directly concerning these features as many people have a hard time understanding the features in detail and may just say “includes VFD’s” or some other general phrase.

We hope this helps anyone researching paint booths. Stay tuned for more on new vs. used!