The Accudraft SS™ is made specifically for facilities looking for high performance and space savings. The SS air makeup unit is completely contained above the booth cabin. The SS™ can be extended in size in any direction. The SS can be configured as a front or rear flowing semi downdraft paint booth system. Installation is fast and easy energy efficiency is maximized. Increase the SS’s drying and curing speeds by adding the Accudraft Xcelerator™ Waterborne paint drying system.

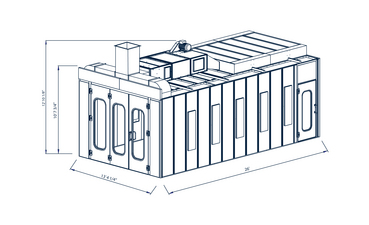

Product Photo (above): Accudraft SS™ w/ 48″ MAGNA II™ ceiling light package.

The SS™ space saver air makeup unit is a completely integrated intake, heat, and heat recycle system designed for high production paint booths. Twin double inlet centrifugal fans provide efficient airflow through the paint booth and recycled direct fire heating provides fast paint curing with maximum energy efficiency. The SS air makeup unit takes up very little overhead space and saves your shop valuable floor space next to the paint booth. more >>

SmartPad™ Digital Controls

Accudraft’s SmartPad™ digital control panel provides the user with all process information and settings in one compact and easy to read paint booth control unit. Monitor workspace airflow and pressure readings, temperature and time of each phase of the finishing process. All processes are automatic and the SmartPad™ comes out of the box ready to integrate accessories such as Accudraft’s Xcelerator™ and/or EnergySmart™ package.

The SS Space Saver paint booth system is available in one of two options. The first is a front air flow semi downdraft configuration which delivers the incoming air through the front half of the paint booth ceiling and exhausts the outgoing air through filtered columns in the rear.

Reverse Air Flow Configuration

The second configuration is called a “reverse air flow” configuration because the flow of air is now entering the rear half of the paint booth ceiling and the exhaust is located next to the front doors. All processes are the same and the energy efficiency is identical. The only difference is that the semi downdraft airflow is now moving from back to front. Depending on the shape and size of your building and where ducts are permitted, a reverse flow paint booth may be the best option for your facility.

Xcelerator™ Waterborne Paint Drying System

Xcelerator™ Waterborne Paint Drying System

The SS Space Saver paint booth can can process jobs even faster with the addition of Accudraft’s Xcelerator™ waterborne paint drying blower system. 32 independently adjustable air jets allow for targeted drying and can reduce drying time by up to 50%. No extra controls or complicated steps. All processes are integrated in the SmartPad right out of the box. more >>

Highlights:

Options: